- Research Field

- We design the future with creative convergence networks in a diversity of research fields such as medium- and small sized ships, offshore plants, green ships, marine leisure equipment, maritime marina.

- Technology Research

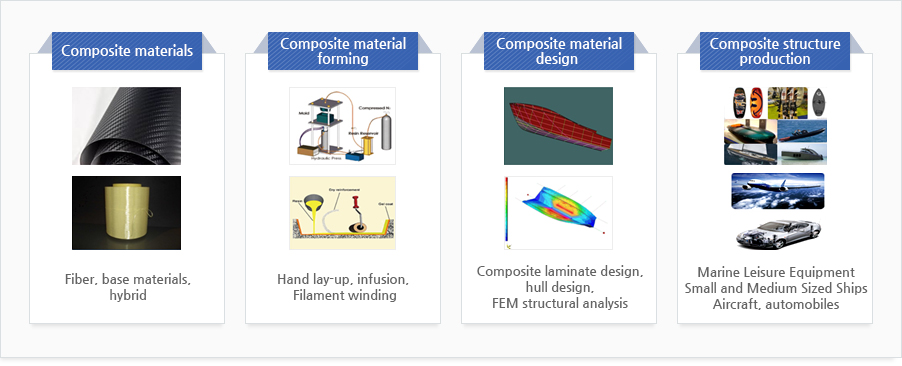

- New Materials for Marine Shipbuilding

- ecause regulations for air pollutants emitted from small boats have been reinforced recently due to global energy and environment regulation issues, it needs to develop technologies for hull weight lightening, fuel efficiency reduction and CO2 decrease.

Accordingly, we use high-performance and light-weight convergence materials to focus on developing shipbuilding, marine leisure equipment and components. -

- High-performance and light-weight shipbuilding and marine leisure equipment development

- High-tech shipbuilding and marine leisure equipment development

- Smart new materials (piezoelectric and shape memory etc.) component development

- Next-generation marine structure convergence materials

- Carbon fiber based marine leisure equipment development and southwest seashore marine leisure belt construction

- Developing high-performance carbon fiber composite materials for marine sport leisure

- Developing carbon fiber personal water leisure crafts and IRC class racing yachts

- Developing high-quality cruise leisure boats with CFRP materials

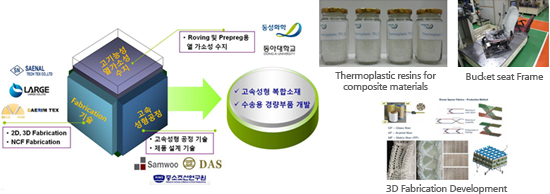

- Developing thermoplastic resin based high-speed forming composite materials and lightweight components for transportation

- Developing thermoplastic resin for high-speed forming

- Developing fabrication technologies for structural parts

- Developing high-speed forming process technologies and lightweight components for transportation

- Developing hulls with vacuum infusion methods applying aramid hybrid fabrics

- Developing aramid hybrid fabric manufacture technologies/Developing the forming process applying vacuum infusion methods

- Developing 30-feet class yacht hull applying aramid hybrid fabrics

- Developing aramid hybrid fabrics for lightweight hulls /Developing lightweight hulls applying vacuum infusion methods

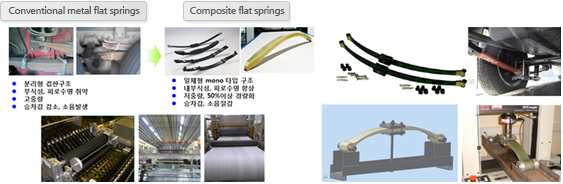

- Developing flat springs applying fast-hardening thermosetting prepreg with lighter by more than 50%

compared to metals - Researching the resin system by giving fast-hardening and toughening and developing carbon fiber prepreg

- Developing the composite material flat spring forming system applying compression molding

- Final product’s reliability evaluation and the vehicle mounted environment’s durability performance test evaluation

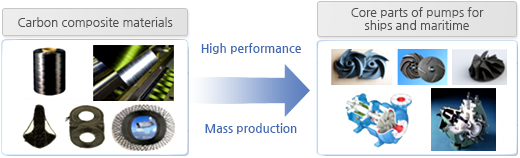

- Developing marine impeller fabrics applying carbon fibers and impeller manufacture technologies

- Developing technologies to manufacture fabrics applying carbon fibers for impellers

- Developing the carbon fiber block forming process applying the rear panel laminating method

- Developing CFRP impeller processing technologies and products with carbon fiber blocks

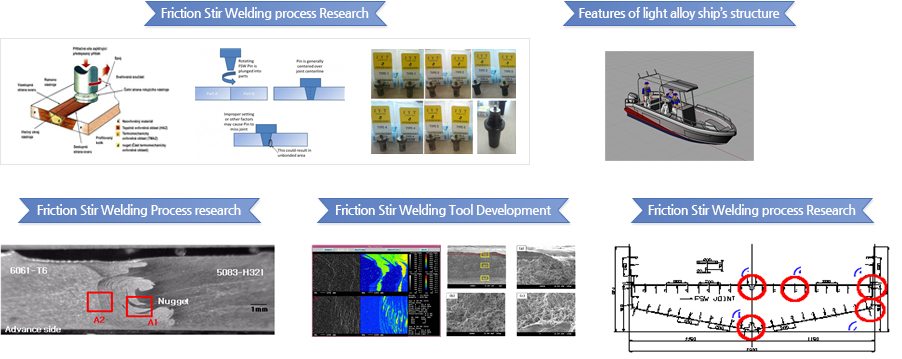

- Light alloy material technology development

- Friction stir welding process research

- riction stir welding tool development

- Feature analysis of FSW sleeve pieces